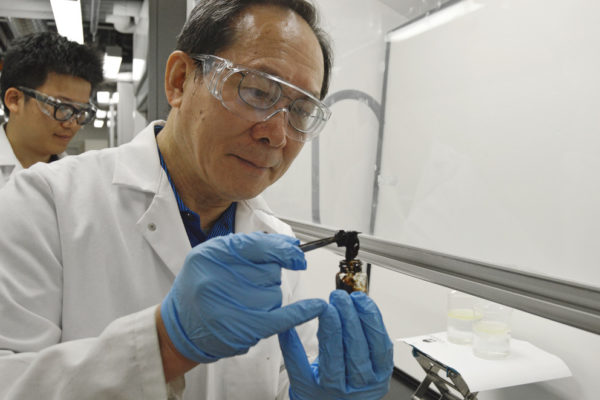

The synthetic material is called i-Petrogel. It absorbs more than 40 time its weight in crude oil, and it also completely stops oil from spreading after the initial spill. “If the recovered oil can’t be reused, it needs to be dumped somewhere. It’s useless,” said T.C. Mike Chung, professor of materials science and engineering at Penn State.

“That’s why we developed a technology that is comprehensive. i-Petrogel is a polymer made from oil. It’s a pure hydrocarbon.”

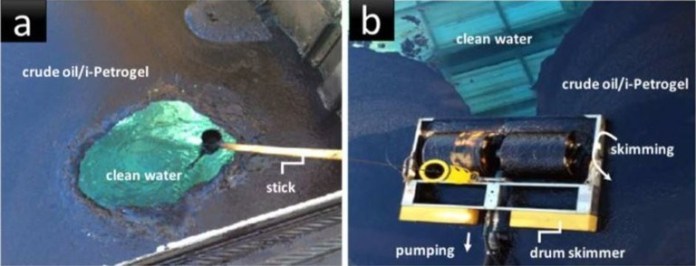

Two gallons of fresh Alaska North Slope oil were released in figure A. The oil is treated with i-Petrogel in figure B. As you can see the differences between the spill and the absorbed material are massive. The oil reduced to ¼ of its original size and clumps up to make it easier to recover. i-Petrogel isn’t the first material that these scientists have worked with. Petrogel is i-Petrogels predecessor and only absorbs half as much as its newer incarnation. One of i-Petrogel’s best features is how it absorbs oil. i-Petrogel becomes gel-like when it begins to absorb oil and then floats to the top. From here, already used skimmers, can be used to easily collect the oil and transfer it to a refinery.

Various oil recovery methods have been tested and used. Yet, none of them have come close to the versatility that i-Petrogel is offering. Chung says that i-Petrogel pays for itself with just the oil it recovers. One pound of i-Petrogel costs ~$2 to manufacture and less than eight pounds of the synthetic material are needed to clean up one barrel of crude oil. In today’s prices, $16 worth of i-Petrogel would recover ~$85 worth of crude oil. It’s a very cost effective method of oil recovery and oil clean up. The main factors left to consider is how long it takes to produce one pound of the material and how viable it is to use in an extreme spill situation.

For more information, follow us each week for the latest hazmat news or contact HazmatHub here.